In manufacturing and packaging industries, accurate labeling is crucial for both regulatory compliance and effective product identification. Incorrect or missing information on labels can lead to legal issues, customer dissatisfaction, and significant financial losses. To address these challenges, businesses are increasingly adopting automated Label Inspection systems, which ensure precision and reliability throughout the labeling process.

Understanding Label Inspection

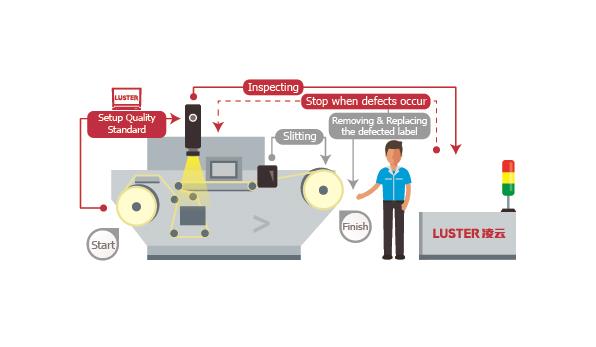

Label inspection is the process of systematically verifying that labels on products meet predefined standards. This involves checking for correct text, barcodes, graphics, placement, and overall print quality. Unlike manual inspection, which can be inconsistent and time-consuming, automated systems provide continuous, high-speed verification. Many manufacturers integrate a Label Inspection solution into their production lines to ensure every product is correctly labeled and compliant with industry regulations.

Ensuring Compliance with Regulations

One of the primary reasons for implementing label inspection systems is to maintain regulatory compliance. Different industries have strict labeling requirements, from nutritional information in the food sector to safety warnings on chemicals or pharmaceuticals. Failure to meet these standards can result in fines, product recalls, or damage to a company’s reputation. Automated inspection systems reduce the risk of non-compliance by verifying every label against pre-set rules and standards.

Improving Product Identification and Traceability

Accurate labels are essential for proper product identification and traceability. Barcodes, QR codes, and serial numbers play a critical role in inventory management, supply chain tracking, and customer service. Label inspection systems ensure that these identifiers are correctly printed and positioned, enabling efficient scanning and reducing errors during distribution.

Reducing Waste and Production Costs

Labeling mistakes can lead to significant material waste and financial loss. Misprinted or misplaced labels often require rework or scrapping of products, which increases production costs. Automated label inspection systems detect errors in real-time, allowing immediate corrections before products leave the production line. This proactive approach minimizes waste and enhances overall operational efficiency.

Enhancing Brand Reputation

Consistently accurate labeling reflects positively on a brand. Errors on product labels can lead to confusion, product returns, and loss of customer trust. Implementing a reliable label inspection system ensures that all products leaving the facility meet high-quality standards, reinforcing customer confidence and brand reputation.

Data-Driven Quality Control

Modern label inspection systems offer robust data collection and analytics capabilities. They generate detailed reports on defect types, frequency, and trends, enabling manufacturers to identify recurring issues and optimize their processes. This data-driven approach supports continuous improvement in labeling accuracy, quality control, and production efficiency.

Flexibility and Adaptability

Label inspection systems are versatile and can be customized to suit various products and labeling types. Whether handling food packaging, pharmaceutical bottles, cosmetic containers, or consumer goods, these systems can adapt to different sizes, materials, and designs. The flexibility ensures reliable inspection without compromising speed or accuracy.

Conclusion

Label inspection is a critical component of modern manufacturing, ensuring compliance with regulations, accurate product identification, and operational efficiency. By detecting errors early, minimizing waste, and providing data-driven insights, label inspection systems protect both brands and consumers. For companies focused on delivering precise, reliable, and compliant products, adopting a label inspection system is a strategic step toward long-term success.

George is the voice behind Wisdomised, a news blog dedicated to delivering fresh, engaging stories that keep readers both informed and entertained. With a sharp eye for current events and trending topics, George crafts posts that make complex news accessible and enjoyable. His unique perspective and storytelling skills bring a refreshing twist to every update, inviting readers to explore the world through Wisdomised.