An Agitated Nutsche Filter Dryer (ANFD) is a versatile piece of equipment widely used in the pharmaceutical, chemical, and food industries for filtration, washing, and drying of solids. It is designed to handle batch processing of products that are sensitive to contamination or require controlled drying conditions. By combining the functions of a filter and a dryer in a single unit, an ANFD reduces processing time, minimizes product loss, and ensures high purity standards.

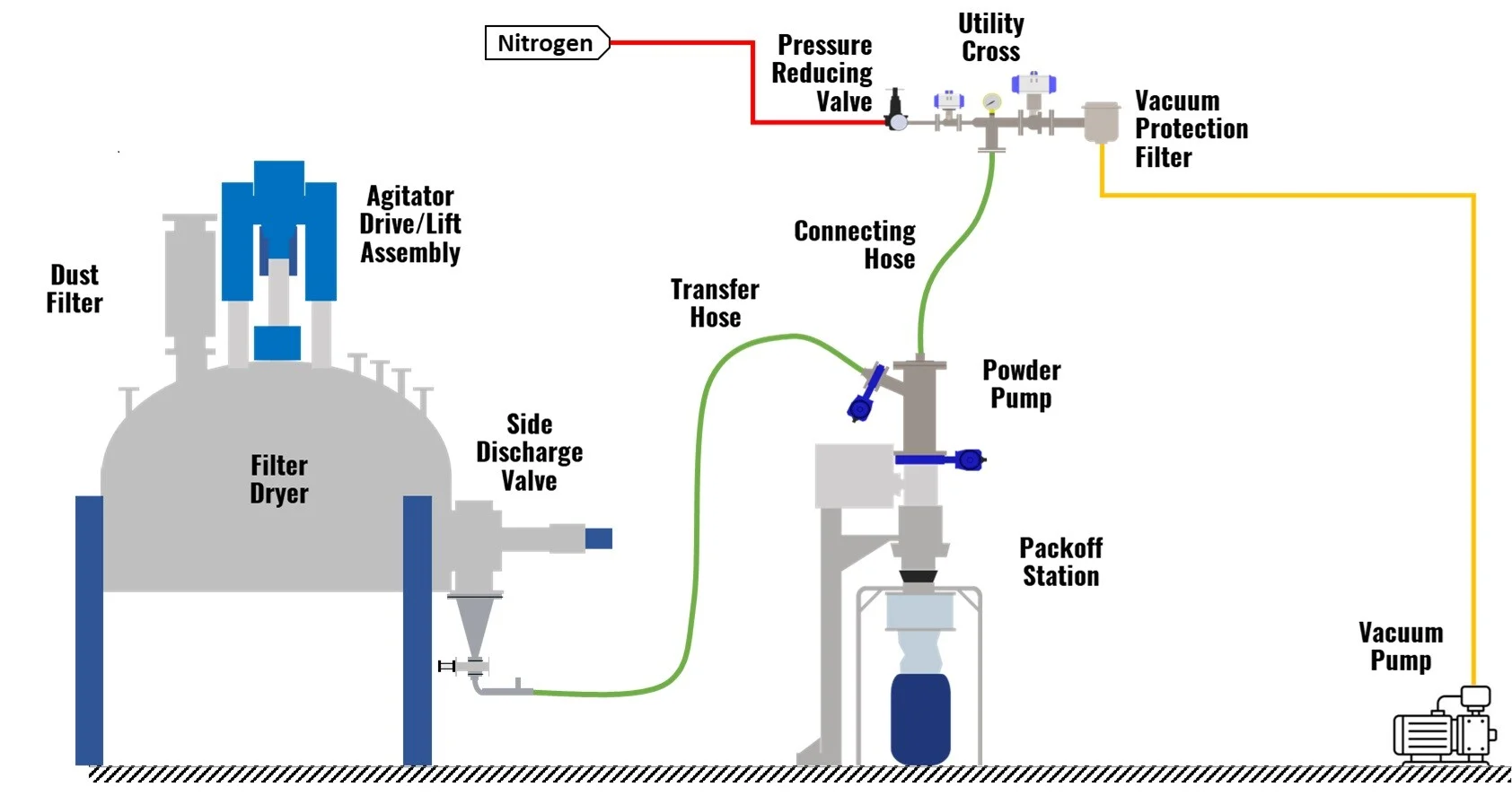

The primary purpose of an Agitated Nutsche Filter Dryer is to efficiently separate solids from liquids while also allowing for subsequent washing and drying without transferring the product between different equipment. This process is particularly crucial for products that are heat-sensitive or prone to contamination. The equipment typically consists of a cylindrical vessel with a perforated bottom plate, a mechanical agitator, and a vacuum system. The agitator allows for uniform mixing and prevents caking of solids during filtration and drying. For more detailed specifications and purchasing options, you can explore this Agitated Nutsche Filter Dryer which is commonly used in industrial applications.

Design and Components

An Agitated Nutsche Filter Dryer is made up of several essential components that work together to achieve efficient solid-liquid separation and drying:

- Vessel Body: Usually constructed from stainless steel to resist corrosion and maintain product purity, the vessel is designed to withstand vacuum and pressure conditions. The interior can be polished or coated depending on the product requirements.

- Filter Plate: Located at the bottom of the vessel, this plate supports the filter medium (such as cloth, paper, or mesh) and allows liquid to pass through while retaining solids. The plate may also be perforated to allow for uniform liquid drainage.

- Agitator System: The mechanical agitator is a key component that mixes and scrapes the solids during drying. It can have different designs, including plough, anchor, or paddle types, depending on the material’s characteristics. Agitation prevents hard cake formation, ensuring more uniform drying.

- Vacuum and Heating Systems: Most ANFDs are equipped with a vacuum system to remove filtrate and moisture efficiently. Additionally, the vessel walls and filter plate can be jacketed for steam or thermal oil circulation, providing controlled heating for drying the product.

- Discharge Mechanism: Once filtration and drying are complete, the agitator helps in discharging the solids. Some models have bottom discharge valves, while others use tilting or rotating mechanisms to remove the product.

Working Principle

The operation of an Agitated Nutsche Filter Dryer involves several stages:

Filtration

The process begins by charging the vessel with a slurry containing both solids and liquids. The vacuum system is activated, drawing the liquid through the filter medium while the solids remain on the filter plate. During this stage, the agitator may rotate slowly to prevent the solids from forming a compact cake that is difficult to dry.

Washing

After most of the liquid has been removed, the solids can be washed directly in the same vessel. A washing solvent is added to the cake, and the agitator stirs the solids gently, ensuring thorough mixing and removal of impurities. This stage is critical in pharmaceutical and chemical applications, where high purity is required.

Drying

Following washing, the drying phase begins. The vessel walls and filter plate are heated to evaporate the residual moisture in the solids. The agitator scrapes and mixes the solids continuously, promoting even heat distribution and preventing localized overheating or caking. The vacuum assists in lowering the boiling point of the remaining moisture, which accelerates drying and preserves heat-sensitive products.

Discharge

Once drying is complete, the product is discharged using the agitator system or a specialized discharge valve. The design ensures that the product can be removed with minimal manual handling, reducing contamination risk and product loss.

Advantages of Agitated Nutsche Filter Dryers

The ANFD offers several benefits over traditional filtration and drying methods:

- Single Equipment for Multiple Steps: It integrates filtration, washing, and drying in one unit, reducing equipment footprint and process time.

- Controlled Environment: Sealed operation prevents contamination and allows for handling of toxic or sensitive products safely.

- Efficient Drying: The combination of heating, vacuum, and agitation ensures uniform drying and minimal residual moisture.

- Reduced Product Loss: Minimal transfer between equipment reduces the chances of product loss and contamination.

- Versatility: Suitable for a wide range of materials, including powders, crystals, and slurries, making it a flexible choice for various industries.

Applications

Agitated Nutsche Filter Dryers are commonly used in:

- Pharmaceuticals: Drying active pharmaceutical ingredients (APIs) and intermediates while maintaining purity.

- Chemicals: Handling fine chemicals, pigments, and catalysts.

- Food Industry: Processing ingredients that require careful handling to maintain quality and safety.

In conclusion, the Agitated Nutsche Filter Dryer is a vital piece of equipment in modern industrial processing. Its ability to combine filtration, washing, and drying in a controlled environment makes it invaluable for industries requiring high-quality, contaminant-free products. By understanding its components, working principles, and benefits, operators can maximize efficiency, improve product quality, and ensure consistent results.

George is the voice behind Wisdomised, a news blog dedicated to delivering fresh, engaging stories that keep readers both informed and entertained. With a sharp eye for current events and trending topics, George crafts posts that make complex news accessible and enjoyable. His unique perspective and storytelling skills bring a refreshing twist to every update, inviting readers to explore the world through Wisdomised.