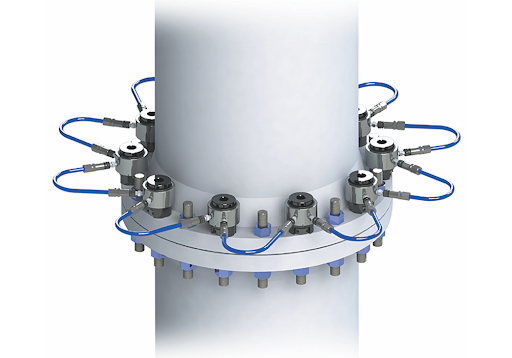

Reliable bolt connections are critical for industrial safety, efficiency, and equipment longevity. Traditional torque-based methods can lead to uneven clamping, human error, and potential joint failures. Hydraulic bolt tensioning addresses these challenges by applying a controlled axial load across bolts, ensuring uniform clamping and eliminating stress inconsistencies. This technology is essential in high-pressure applications such as pipelines, pressure vessels, and heavy machinery.

In this blog, we explore how bolt tensioning guarantees accurate and dependable connections, enhancing operational safety and industrial performance.

Achieving Uniform Bolt Preload for Optimal Joint Integrity

- Consistent Clamping Force: Hydraulic systems provide exact axial tension to every bolt, ensuring even load distribution across all fasteners. This prevents uneven stress that could weaken joints or compromise structural integrity over time.

- Maintaining Structural Alignment: Uniform preload keeps flanges, joints, and assemblies precisely aligned during operation. Proper alignment reduces wear and maintains reliable performance under high-pressure conditions.

- Minimizing Stress Concentration: By distributing force evenly, hydraulic tensioning lowers localized stress on bolts and surrounding components. This reduces the risk of fatigue, cracking, or premature failure in critical assemblies.

Ensuring uniform preload is fundamental to safe, long-lasting industrial connections.

Reducing Human Error and Enhancing Workplace Safety

- Eliminating Manual Torque Risks: This removes the need for manual torque application, reducing errors caused by inconsistent force. This ensures that bolts are tightened accurately and safely every time.

- Safer Operations: Operators are protected from high torque forces and mechanical hazards associated with manual tightening. This creates a safer work environment and minimizes the risk of injuries.

- Consistent Results: Each tensioning cycle delivers precise, repeatable results, ensuring uniform bolt preload across all connections. Consistency is particularly crucial in high-pressure or high-risk industrial applications.

Automation and precision make hydraulic systems safer and more reliable than conventional methods.

Boosting Efficiency and Minimizing Maintenance Downtime

- Faster Bolt Installation: Hydraulic systems speed up the bolt tensioning process, significantly reducing assembly time. This allows maintenance and installation tasks to be completed more efficiently, saving labor and operational costs.

- Real-Time Adjustments: Operators can adjust bolt tension on the spot without disassembling the assembly. This capability streamlines maintenance, reduces errors, and minimizes delays during critical operations.

- Operational Continuity: Faster installation and precise adjustments reduce equipment downtime, keeping machinery running smoothly. Continuous operations optimize production schedules and enhance overall industrial productivity.

Hydraulic tensioning enhances workflow efficiency while maintaining high safety standards.

Extending Equipment Lifespan with Accurate Connections

- Reducing Bolt Fatigue: Applying precise axial load minimizes micro-movements and mechanical wear on bolts and flanges. This extends their service life and reduces the need for frequent replacements.

- Maintaining Seal Integrity: Proper hydraulic tensioning ensures bolts hold flanges tightly, preventing leaks in pipelines, reactors, and other pressurized systems. Reliable sealing safeguards equipment performance and operational safety.

- Reliable Performance Over Time: Accurate and uniform bolt connections reduce stress on adjoining components, preventing premature failure. This ensures durable, trouble-free operation across the entire assembly.

Accurate bolt tensioning directly contributes to long-term operational reliability and cost savings.

Final Thoughts

Hydraulic bolt tensioning is indispensable for industries that demand precision, reliability, and operational safety. By providing uniform bolt preload, reducing human error, and supporting efficient maintenance, it guarantees secure, long-lasting connections in critical applications.

Companies looking to enhance assembly accuracy and equipment reliability can explore advanced solutions, including a heat exchanger tube expander from Powermaster America LLC, ensuring safer operations and consistent performance across industrial operations.