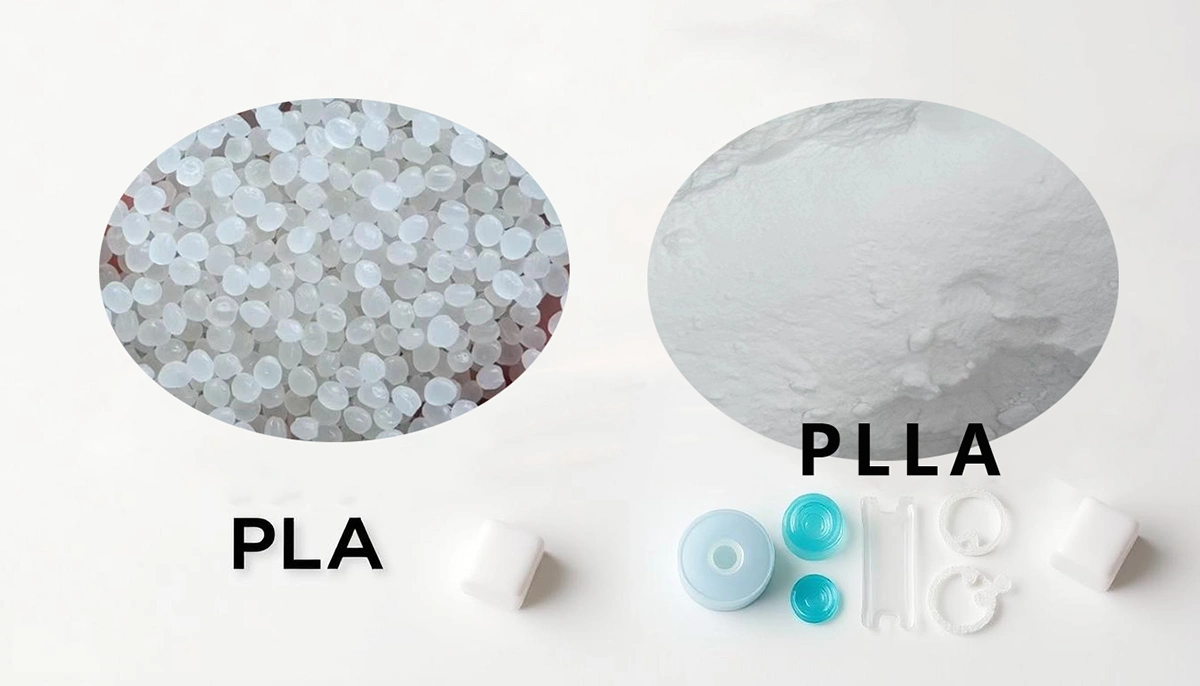

Biopolymers have gained significant attention as sustainable alternatives to conventional plastics, particularly in medical, industrial, and environmental applications. Among these materials, Poly-L-lactic acid stands out due to its strong mechanical properties, biocompatibility, and predictable biodegradation. However, like all materials, PLLA has both advantages and limitations when compared to other commonly used biopolymers such as polyglycolic acid, polycaprolactone, and starch-based polymers. Understanding these differences helps manufacturers and researchers select the most appropriate material for specific applications.

Overview of Biopolymers and Material Context

Biopolymers are polymers derived from renewable biological sources or designed to biodegrade under natural conditions. They are widely used in fields where environmental impact, safety, and sustainability are critical considerations. Each biopolymer has a unique combination of properties that influence its performance, processing, and end-of-life behavior.

Within this diverse category, PLLA is often selected for applications that require a balance of strength, stability, and controlled degradation. Compared to softer or faster-degrading biopolymers, PLLA offers higher rigidity and longer-lasting performance, making it especially valuable in medical devices and load-bearing applications.

Mechanical Strength and Structural Performance

One of the key advantages of PLLA over many other biopolymers is its mechanical strength. PLLA exhibits high tensile strength and stiffness due to its semi-crystalline structure. This makes it more suitable for applications that require structural support, such as orthopedic implants, fixation devices, and durable packaging.

In comparison, biopolymers like polycaprolactone are more flexible but significantly weaker, limiting their use in load-bearing applications. Starch-based polymers, while inexpensive and biodegradable, often lack the mechanical integrity needed for demanding environments. PLLA’s strength gives it a clear advantage in situations where durability and dimensional stability are essential.

Biodegradation Rate and Predictability

Another important advantage of PLLA is its predictable and controllable degradation rate. The polymer degrades through hydrolysis into lactic acid, which is naturally metabolized by the body and environment. This degradation can be engineered to occur over months or years, depending on molecular weight and crystallinity.

Compared to polyglycolic acid, which degrades very rapidly, PLLA offers longer-term performance. This makes it preferable for applications where sustained support or gradual resorption is required. On the other hand, some biopolymers degrade too slowly or inconsistently, making it difficult to predict their long-term behavior.

Biocompatibility and Medical Reliability

PLLA is widely recognized for its excellent biocompatibility, which has been demonstrated through decades of clinical use. It does not produce toxic byproducts during degradation and is generally well tolerated by the body. This has led to its extensive use in sutures, implants, tissue scaffolds, and drug delivery systems.

While other biopolymers such as polyglycolic acid are also biocompatible, their rapid degradation can lead to localized acidity and inflammation in some cases. PLLA’s slower degradation rate helps minimize these risks, offering a more controlled biological response in long-term medical applications.

Processing Versatility and Manufacturing Considerations

PLLA offers good compatibility with standard manufacturing techniques such as injection molding, extrusion, and 3D printing. This makes it easier to integrate into existing production systems compared to some biopolymers that require specialized processing conditions.

However, PLLA also has limitations in processing. Its relatively high melting temperature and sensitivity to moisture require careful control during manufacturing. In contrast, some biopolymers with lower melting points are easier to process but may lack the performance characteristics needed for advanced applications.

Environmental Benefits Compared to Other Biopolymers

From an environmental perspective, PLLA has several advantages. It is derived from renewable resources and degrades into naturally occurring compounds, reducing long-term environmental impact. Its life cycle generally results in lower greenhouse gas emissions compared to petroleum-based plastics.

When compared to certain biopolymers that rely heavily on agricultural starch, PLLA may offer better performance but at a higher production cost. Additionally, some biopolymers are compostable under a wider range of conditions, whereas PLLA often requires industrial composting environments for efficient degradation.

Cost and Economic Limitations

One of the main limitations of PLLA is its cost. Producing high-purity L-lactic acid and controlling polymerization processes can be more expensive than manufacturing simpler biopolymers. This higher cost can limit its use in low-margin or high-volume consumer products.

Other biopolymers, such as starch-based plastics, are often more affordable but sacrifice performance and durability. As production technologies improve and economies of scale increase, the cost gap between PLLA and alternative biopolymers is expected to narrow.

Flexibility and Material Modification Challenges

PLLA is inherently more rigid and brittle than some other biopolymers. This limits its use in applications that require high flexibility or impact resistance. To overcome this, PLLA is often blended with other polymers or modified with plasticizers, which can add complexity to material design.

In contrast, biopolymers like polycaprolactone naturally offer greater flexibility but lack the strength and stability of PLLA. Material selection therefore involves balancing mechanical performance with flexibility requirements.

Conclusion

PLLA offers a strong combination of mechanical strength, biocompatibility, and controlled biodegradation that sets it apart from many other biopolymers. Its advantages make it particularly well suited for medical and high-performance applications. However, higher costs, limited flexibility, and specific processing requirements present notable limitations. When compared to other biopolymers, PLLA stands out as a premium material designed for reliability and long-term performance rather than low-cost, disposable use.

George is the voice behind Wisdomised, a news blog dedicated to delivering fresh, engaging stories that keep readers both informed and entertained. With a sharp eye for current events and trending topics, George crafts posts that make complex news accessible and enjoyable. His unique perspective and storytelling skills bring a refreshing twist to every update, inviting readers to explore the world through Wisdomised.