In modern electronics, devices are getting smaller, faster, and smarter. Behind these improvements lies one key technology — the advanced printed circuit board (PCB). From smartphones and automotive systems to medical and aerospace electronics, advanced PCBs enable higher speeds, greater power density, and more complex layouts within compact spaces.

What Counts as an Advanced Printed Circuit Board

An advanced printed circuit board goes beyond the standard 2- or 4-layer design. It includes fine lines and spacing, multiple layers, microvias, buried or blind vias, impedance control, and specialised materials for thermal and high-frequency performance. These boards are designed to ensure stable signal integrity, excellent mechanical reliability, and efficient heat management.

For engineers and product developers, using advanced PCBs enables higher density and improved functionality without increasing the overall size of the product.

Common Types and Materials

Advanced PCB technology covers several board types:

- HDI (High-Density Interconnect) PCBs for compact and high-speed devices.

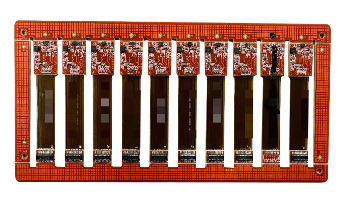

- Rigid-Flex PCBs that combine flexibility and durability for foldable or space-limited designs.

- High-Frequency / Microwave PCBs made with PTFE or Rogers materials, ideal for 5G, radar, and RF communication.

- Thick-Copper or Metal-Core PCBs for power devices and thermal management.

The materials vary according to the performance need. Standard FR-4 works well for most digital applications, while low-loss materials such as PTFE, Taconic, or Isola are used for high-frequency circuits. Aluminium- or copper-based substrates help improve heat dissipation in power and LED modules.

Advanced Circuit Board Production — How It’s Built

Producing an advanced circuit board requires precise control at every step.

1. Lamination and Stack-Up – Multiple layers are pressed together under high temperature and pressure. Sequential lamination allows blind and buried vias and ensures precise alignment of internal layers.

2. Imaging and Etching – Laser Direct Imaging (LDI) enables fine traces down to 50–75 μm, improving circuit density and accuracy. Controlled impedance and uniform copper thickness are verified during production.

3. Drilling and Plating – Laser drilling creates microvias between layers. These are then plated with copper to ensure strong and reliable connections. For thicker boards, mechanical drilling and via filling are used.

4. Surface Finishing – The surface finish protects copper and provides good solderability. Common options include ENIG, ENEPIG, immersion silver, and tin. ENEPIG is preferred for gold wire bonding or fine-pitch BGAs.

At every step, Fast Turn PCB combines automated inspection and process monitoring to ensure consistency and yield.

From Bare Board to Fully Assembled PCBA

Advanced PCBs are only part of the story. Fast Turn PCB provides a complete one-stop solution that covers both PCB fabrication and assembly.

The process includes:

- Engineering review and DFM check – Gerber and BOM files are verified before production.

- PCB fabrication – The board is built using the optimised stack-up and materials.

- Component sourcing – Parts are procured from authorised global distributors.

- SMT and THT assembly – Components are placed with automated machines and soldered with precision reflow and wave processes.

- Inspection and testing – AOI, X-ray, ICT, and functional testing ensure quality.

- Packaging and shipping – Boards are packed for global delivery.

Prototype and small-batch orders can often be delivered within 3–7 working days, depending on complexity.

All production follows ISO 9001, ISO 13485 (medical), and IPC-A-610 Class 2 or 3 standards.

DFM and High-Speed Design Checklist

For high-performance boards, Design for Manufacturability (DFM) is essential. Here are key guidelines:

- Define layer stack-up and impedance requirements early.

- Maintain consistent copper thickness and spacing across layers.

- Use microvia or via-in-pad only where needed to control cost.

- Plan escape routing for BGAs and fine-pitch components.

- Match the CTE (coefficient of thermal expansion) of materials to avoid stress during reflow.

- Add thermal vias or copper areas to improve heat dissipation.

- Include test points and fiducials for assembly and inspection.

Fast Turn PCB’s team provides free DFM feedback before production, helping customers reduce rework and lead time.

Where Advanced PCBs Shine

Advanced PCBs are used across a wide range of industries:

- 5G and RF communications – Low-loss PTFE materials ensure signal clarity.

- Automotive and ADAS – High reliability and heat tolerance under harsh conditions.

- Industrial control – Multi-layer rigid boards support complex automation systems.

- Medical electronics – Clean assembly and traceability with ISO13485 standards.

- Power and computing – Thick-copper boards handle higher currents efficiently.

Whether it’s a high-frequency radar or an IoT control board, each application benefits from tailored materials and a precise stack-up design.

Why Choose Fast Turn PCB

Fast Turn PCB offers full in-house capabilities for both PCB fabrication and PCBA assembly. With over 350 employees and dedicated manufacturing lines, the company serves global clients from prototype to mass production.

Key strengths include:

- Broad capability range – HDI, rigid-flex, high-frequency, thick-copper, and multi-layer PCBs.

- Certifications: ISO 9001, ISO 13485, UL, and RoHS compliance.

- Strict standards – Built to IPC-A-600/610 Class 2 or 3.

- Fast delivery – Rapid prototyping and reliable global logistics.

Customers across North America and Europe trust Fast Turn PCB for consistent quality, transparent communication, and quick engineering feedback.

Conclusion

Advanced printed circuit boards are the foundation of today’s smart and compact electronics. From HDI and rigid-flex to RF and power boards, each type brings unique benefits — but all require precision engineering and reliable production.

With complete in-house manufacturing, DFM support, and global delivery, Fast Turn PCB ensures that your advanced designs are turned into high-quality products, on time and on budget.

George is the voice behind Wisdomised, a news blog dedicated to delivering fresh, engaging stories that keep readers both informed and entertained. With a sharp eye for current events and trending topics, George crafts posts that make complex news accessible and enjoyable. His unique perspective and storytelling skills bring a refreshing twist to every update, inviting readers to explore the world through Wisdomised.